Method 1: Enhance technological degree, stabilize item quality, and reinforce technical books:

According to the survey, only a few manufacturers of polycarboxylic acid water reducer items in my country are independently developed, and a lot of other makers present technology from university study establishments or research study institutes or straight present innovation from other companies to begin manufacturing. Due to the restricted technological strength of the manufacturers themselves, they do not have a deep understanding of the polycarboxylic acid water reducer technology they produce, and it is hard to adapt to various adjustments in resources and procedures, and there is no way to talk about the security of item top quality. Therefore, it is suggested that polycarboxylic acid water-reducing agent makers proactively accept universities and study institutes to completely recognize the different variables influencing the performance of polycarboxylic acid water-reducing agent products, change the synthesis process parameters in a timely fashion to stabilize product quality, and enhance technical books via joint or independent research and development to adjust to market need. Additionally, the early release of polycarboxylic acid water-reducing agent raw material requirements and the stability of polycarboxylic acid water-reducing agent raw material rates are likewise extremely vital to make certain the security of polycarboxylic acid water-reducing agent product efficiency.

Technique 2: Idea in examination results instead of item specifications

Some products that are fantastic in the water-reducing agent requirements, or perhaps products with excellent test outcomes, might not be suitable for a particular task. On the contrary, some items might satisfy the demands of concrete material preparation for a particular task even though the examination results are not really impressive. In addition, due to modifications in resources, the test results during job bidding process can not represent the real application of the task. GB50119-2003 “Technical Specifications for Application of Concrete Admixtures” “2.1.4” plainly states: The raw products utilized in concrete with admixtures, such as concrete, sand, stone, admixtures, and admixtures, will comply with the arrangements of the appropriate national standards in force; when trial-mixing concrete with admixtures, the raw products made use of in the job shall be utilized, and the examination items will be established according to the style and building and construction demands. The examination problems will be the same as the building conditions. When the raw materials used in the job or the concrete efficiency needs alter, the trial-mixing test will be conducted once more.

(Cabr superliasticizer)

Technique 3: Avoid get in touch with between polycarboxylic acid water reducers and iron products

For polycarboxylic acid water reducer makers and suppliers, unique production tools and assembly line will be used to manufacture and worsen polycarboxylic acid water reducers, and polycarboxylic acid water reducers shall not be synthesized or worsened making use of the same assembly line as various other water reducers. In addition, the transportation and storage of polycarboxylic acid water reducers will not utilize iron products (other than stainless steel) yet plastic, glass and other materials. Call with iron in some cases causes changes in the efficiency of polycarboxylic acid water reducers.

Method 4: Resolutely avoid mixing other types of admixtures

It is purely forbidden to blend various other water reducers or various other types of admixtures. There are two meanings. First, the compounding of polycarboxylic acid water reducers (such as with lignin sulfonate, air entrainment, defoaming, retarding and various other components) can only be accomplished by admixture makers or suppliers. The user of the water reducer, that is, the concrete preparer, only needs to evaluate and save its pertinent performance. Nothing else parts may be intensified in it, nor may other parts be mixed in it because of oversight. It is definitely restricted to use pumps and metering devices for pumping and metering other admixtures without cleaning. One more significance is that concrete mixing devices, transport automobiles, and pumping equipment are best utilized for concrete mixed with polycarboxylic acid water reducers. When sharing blending devices, transportation lorries and pumping devices, these devices needs to be completely cleaned before they can be utilized for concrete combined with other types of admixtures, and vice versa.

Method 5: Strictly determine the water reducer and mix water

When preparing concrete combinations with polycarboxylic acid water reducers, the optimum water reducer dose and water intake determined by the research laboratory should be strictly measured. Do not boost the water reducer dose or water consumption at will certainly to stay clear of negative sensations such as partition, bleeding, solidifying, and enhanced air content in the mixed concrete, which will impact the normal pumping building and construction and pouring quality of the concrete.

The dampness contained in the raw products sand and stone aggregates need to be precisely gauged and subtracted from the complete water intake to prevent adverse effects triggered by imprecise detection of the dampness consisted of in the sand and rock accumulations.

( concrete addtives)

Method 6: Properly deal with the compatibility trouble of polycarboxylic acid water reducers and cement/admixtures

The compatibility trouble of admixtures and cement/admixtures has a long background. Over the years, the versatility research work on naphthalene-based high-efficiency water-reducing representatives and their compound products has actually attained great outcomes:

With the hard work of scientists, concrete preparers, admixture producers, concrete and admixture makers, concrete erectors and managers have actually collectively acknowledged this problem, transforming the situation in which admixture makers and providers have actually always presumed all responsibilities.The conflict of admixtures and cement/admixtures is attributed to lots of influencing factors, and thorough research study has been accomplished on their influencing legislations. A series of effective remedies have actually been checked out for the certain incompatibility between admixtures and cement/admixtures.

Method 7: Purely control the vibration radius and vibration time

Considering that the slump of concrete prepared with polycarboxylic acid-based water-reducing agents is generally big and the viscosity of the mix is reduced, the resonance span and vibration time after the concrete mix is put need to be determined through experiments or should be assisted by professionals. Intend the vibration radius is also small or the resonance time is also long. Because case, it is very easy to create architectural defects such as a serious reduction in concrete air material and severe stratification of the accumulated stage and paste stage.

Technique 8: Enhance initial maintenance and protect against cracking.

On any type of occasion, for any type of concrete mix, preliminary and later maintenance after pouring is extremely crucial.

Polycarboxylic acid water reducer has little effect on the contraction efficiency of concrete; simply put, the addition of polycarboxylic acid water reducer does not excessively raise the shrinkage of concrete, which does not suggest that the concrete with polycarboxylic acid water reducer can unwind or even terminate the maintenance.

Like concrete with various other admixtures, the second surface denigration, film covering or spraying of concrete with polycarboxylic acid water reducer after pouring and resonance is really effective in avoiding its plastic shrinking splits. Continuous 7d or 14d moisturizing maintenance is not only essential for the regular growth of concrete toughness but also a warranty to prevent its drying out shrinkage splits.

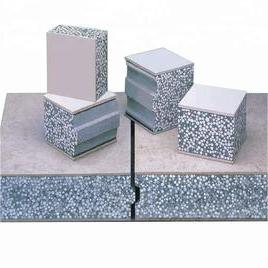

( foamed concrete)

In order to enhance the fracture resistance of concrete with polycarboxylic acid, it is additionally necessary to add a certain amount of fiber, and this type of concrete still requires excellent damp healing to ensure that the structure does not split.

Method 9: Construction and management systems ought to function carefully with concrete prep work and admixture suppliers

In the job, it is inevitable to run into different technical problems, technological conflicts and also problems and conflicts caused by design accidents. The utmost goal of all parties involved in the job is to guarantee the smooth progress of the task and the quality of the project. The background of polycarboxylic acid water reducers in manufacturing and application in actual tasks is really brief, and the built up engineering experience can be better. It is easy to experience application issues and also bring about engineering accidents right now, the building and construction device or management system requires to function very closely with the concrete preparation, polycarboxylic acid water reducer production and supply, and cement/admixture production and supply from a technological perspective and conduct extensive evaluation to propose effective services.

Vendor

Cabr-Concrete is a supplier of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality Concrete Admixture, please feel free to contact us and send an inquiry.

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us