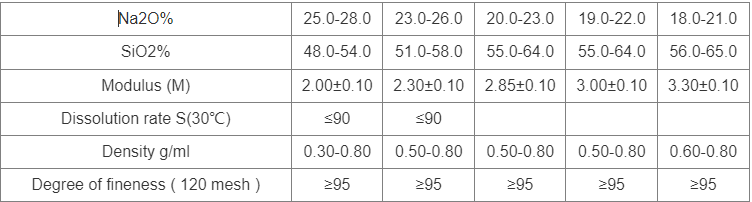

Technical Parameters of Powdered Immediate Salt Silicate (CAS 1344-09-8)

(Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8))

Note: We can likewise tailor sodium silicate powder with moduli of 2.45, 2.5, and 3.4 according to your needs.

Our Series Of Salt Silicate Moduli

We offer powdered immediate salt silicate with moduli ranging from 2.0 to 3.3. Furthermore, we can tailor salt silicate powder with moduli of 2.45, 2.5, and 3.4 to fulfill your certain demands.

Salt silicate, additionally known as water glass, has actually garnered significant rate of interest owing to its large range of applications throughout diverse industries.

Made up of salt oxide (Na2O) and silicon dioxide (SiO2), this substance can be located in types ranging from solid granules to liquid solutions, depending on the ratio of these 2 parts. Its distinct attributes, consisting of solid sticky buildings, durable thermal stability, and acid resistance, provide it a crucial product in fields such as building and construction, automotive manufacturing, and other production markets.

Versatile Utilizes Throughout Industries

In the building industry, sodium silicate acts as an essential part in concrete sealers and fireproofing agents, boosting toughness and safety and security. It is also used in the production of adhesives and binders for making abrasive materials and refractory products. In the automotive industry, sodium silicate is essential for making molds for casting engine components due to the fact that it can withstand high temperatures without wear and tear. Additionally, its usage in water treatment procedures for softening difficult water highlights its flexibility in resolving environmental concerns.

Environmental and Security Considerations

In spite of its prevalent use, the handling of salt silicate requires cautious consideration of environmental and safety and security guidelines. While it is usually taken into consideration risk-free, prolonged direct exposure can trigger skin inflammation, and its dust can irritate the breathing system. Adherence to proper disposal techniques is crucial to avoid contamination of water bodies and the subsequent injury to marine microorganisms. Makers and customers are increasingly embracing sustainable methods to reduce the environmental impact of salt silicate production and use.

( sodium silicate)

Verdict

The overview for salt silicate is bright as researchers remain to discover new usages and enhance existing applications. Offered the continuous technical advancements and the enhanced emphasis on sustainability, this multi-faceted compound is set to play an increasingly main function in driving commercial innovations. As industries progress, so as well will certainly the ways in which salt silicate adds to meeting the obstacles of the 21st century.

Top notch Salt Silicate distributor

TRUNNANO is a supplier of Sodium Silicate Materials with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about liquid glass epoxy, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us